Seal Systems

Designed for Industry

Gaskets, scrapers, and hydraulic and pneumatic seals.

Technical consulting, custom manufacturing, and 3D catalog for design.

Alongside the best technology partners to ensure quality and continuity of supply

About us

Seal Solutions for Major Industrial Applications

We design and supply high-performance sealing systems for a wide range of industries.

From marine to mobile hydraulics, automotive to machine shops, and even food, pharmaceutical, and cosmetic companies that require certified and MOCA-compliant materials.

Our seals guarantee reliability, precision, and durability in any working condition.

Experience

Numbers That Speak

For over thirty years we have been supporting Italian and European companies with

sealing systems designed to ensure business continuity, quality of service and speed in delivery.

38500

+

Coded items always in stock

2

SML-500 CNC lathes dedicated to the production of custom seals

1990

Founding year: more than 3 decades of technical experience

36

hr

Average shipping time for prompt delivery products

You still don't have a clear idea but you have a project in your head?

Do you need more information or do you want to contact us?

Partnership

Sole Authorized Distributor for Emilia Romagna Aston Seals

The quality of the seals we supply also stems from strong>strong and selected partnerships.

For over twenty years Sixten has been an official Aston Seals partner, one of the world's most advanced manufacturers of sealing systems for hydraulics and pneumatics.

Today the new ownership, part of the GMichelin Group, in the person of Managing Director T. Pace, reconfirmed and further consolidated our partnership.

This partnership, built over time and founded on mutual trust, allows us to guarantee our customers performing products, certified materials and constant stock availability.

This is not just a simple supply: it is a daily work of technical alignment, continuous updating and exchange of expertise.

The partnership with Aston Seals represents a distinctive element of our identity: the combination of their production capacity and our technical expertise allows us to be a benchmark in the gaskets and sealing systems market every day.

Full range of high-performance seals

Solutions for industrial, mobile and stationary applications, with high-performance profiles and materials for every need.

Certified and compliant materials

Products that comply with MOCA, FDA, ROHS, REACH and international standards, ensuring safety and reliability.

Consistent and guaranteed quality standards

Each batch follows rigorous processes that ensure stability, continuity and consistently predictable performance.

Rapid procurement

Reduced delivery time through direct flow and constant product availability.

Advanced technical consulting

Direct collaboration with partner engineers to address critical applications and complex designs.

Custom designed solutions

The synergy between our certified partners and the Sixten engineering department allows us to develop optimized sealing systems for each project.

Strength

Why choose Sixten

Sixten doesn't promise: it verifies.

With real tests, field projects, and measurable results.

This is the value of expertise that turns into facts.

Deep knowledge of materials and custom design

In Sixten, knowledge is not theory: it is lived experience. It's the ability to understand what it really takes to build a seal that lasts, resists, and works where others fail.

Each solution is born out of a continuous update on materials, technologies, and the needs of manufacturers.

A "living" and strategic warehouse

In the era of virtual warehouses and last minute procurement, Sixten chooses a different path: always have what you need, before you need it.

This choice allows for production continuity, no downtime, and an immediate response to customer emergencies.

It's not just logistics: it's a way of thinking and working made up of responsibility and presence.

Download

Technical Catalogs

Download catalogs and technical documentation of our gaskets, scrapers and sealing systems.

Materials, profiles, dimensions and specifications for precise and immediate design.

What we do

True passion,

imperfect design

Sixten designs and supplies high-performance sealing systems for every industrial environment.

From hydraulics to pneumatics to food, cosmetics and pharmaceuticals,

we offer specific technical solutions to ensure reliability, safety and operational continuity.

Stem Seals

Each seal is available in different profiles and materials to meet the needs of speed, pressure, and operating conditions.

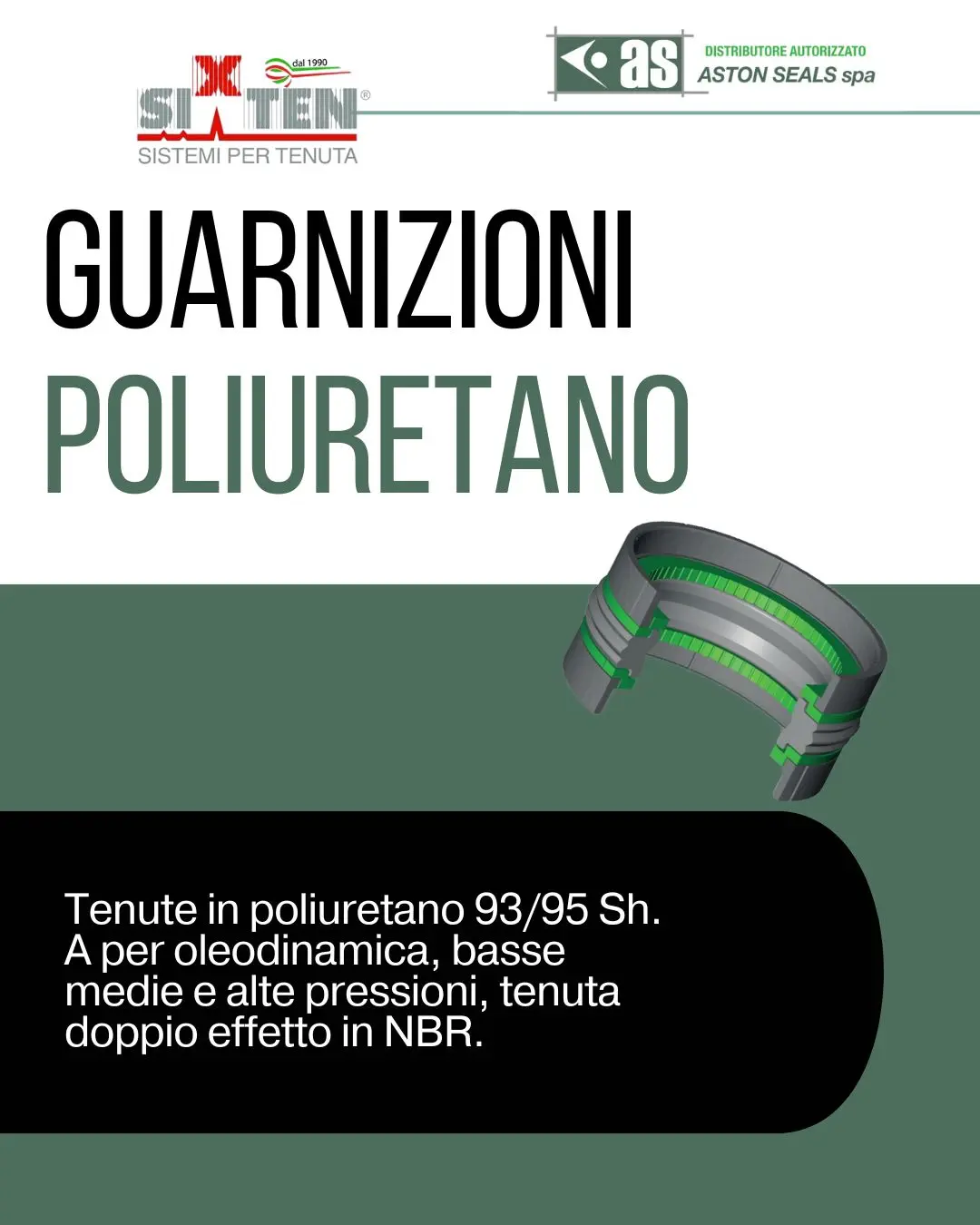

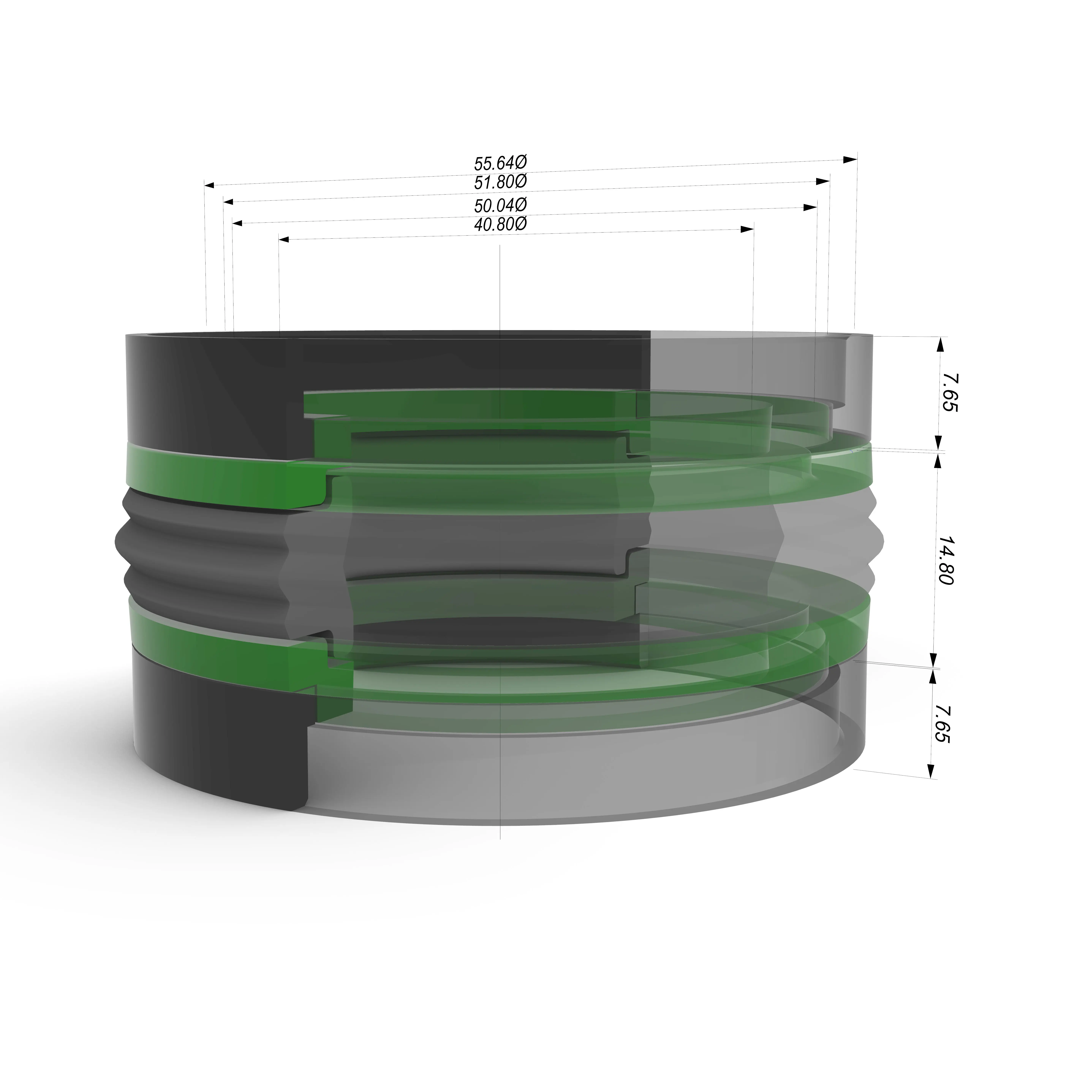

Piston Seals

Our piston seals ensure smooth and controlled operation in cylinders, providing perfect separation of pressure chambers.

Rings and Guide Rings

An indispensable component for guiding pistons and rods, reducing wear and ensuring stability in hydraulic and pneumatic cylinders.

O-ring

Available in a wide range of compounds and specifications, they ensure chemical compatibility, high temperature resistance and long service life.

Rotary shaft seals

Solutions designed for rotating shafts and dynamic applications, with materials and profiles optimized to resist wear and friction.

MOCA

MOCA food safety

Sixten ensures maximum safety in applications where the use of materials intended to come into contact with food, cosmetics and pharmaceuticals is required.

Thanks to a rigorous verification and material selection process, we provide MOCA-compliant gaskets and sealing systems, in full compliance with EC 1935/2004 and EC 2023/2006 regulations.

MOCA compliance is not just a technical requirement for us, but an ongoing commitment to quality, safety and traceability.

The availability of dedicated CNC lathes and certified materials also allows us to manufacture custom MOCA seals, ensuring performance, strength and full safety for the most sensitive applications.

Charity

The Heart Beyond Enterprise

In Sixten, we believe that every entrepreneur should feel fulfilled not only by what they build, but also by what they give back.

That is why we actively support foundations and associations that provide opportunities, care and support to those who face greater challenges every day.

It's a simple gesture, but for us it's a fundamental one: to share part of our success with those who haven't had the same opportunities.

"If life allows you to realize a dream, it's only right to help those who haven't had the same luck."

T. Borsari

FAQ

Frequently asked technical questions

A collection of high-value technical content designed to support technical offices, maintainers and designers in their daily assessments.

The choice of material always starts from three main parameters: fluid, temperature range and operating pressure, to which cyclicities and dynamic conditions (speed, creep, vibration) should be added.

Indicatively:

- NBR: good compromise for mineral oils, medium-high pressure, indicative temperature -20 / +100 °C.

- FKM (Viton®): ideal for higher temperatures, synthetic oils, aggressive fluids and presence of thermal peaks.

- EPDM: suitable for hot water, steam and polar fluids, but not compatible with mineral oils.

- Polyurethane (PU): excellent for dynamic applications, high resistance to abrasion and extrusion, typical for hydraulic rod/piston seals.

- PTFE and filled compounds: for high speeds, low friction and chemically aggressive environment.

In Sixten, the final choice is always made by cross-referencing operating data with data sheets and applicable regulations (e.g., MOCA, FDA) and, when necessary, with specific tests or evaluations with the engineering department.

The most frequent causes are:

- Wrong choice of material with respect to fluid or temperature (stiffening, swelling, cracking).

- Inadequate surface finish of the stem (Ra and Rz out of specification, damaged chrome plating, scoring).

Missing or incorrect sizing of guides: leads to misalignment, transverse loads, and uneven lip wear.

- Incorrect assembly: seal twisting, damage during installation due to sharp edges, corners, or unsuitable tools.

Contamination: inefficient scraper, entry of dust or foreign matter that scuffing rod and seal.

Pressure spikes or water hammer not considered in the design phase.

Sixten often evaluates these aspects with a view to revamping: by analyzing worn seals, it is possible to trace the cause of failure and propose more suitable materials/profiles.

For sliding surfaces (rods and liners) it is essential to respect:

- Surface roughness (Ra, Rz): too low → insufficient lubricating film; too high → accelerated wear and unnecessary leakage. Optimal values depend on the type of seal, but normally stay within a well-defined range with specifications for Ra and Rz.

Hardness and treatment: hard chrome plating, nitriding or specific coatings increase wear and corrosion resistance.

Dimensional tolerances: diameters, ovality and taper must be within the ranges specified by the cylinder design standards.

- Edges and chamfers: inlets must be properly chamfered or filleted to prevent lip damage during assembly.

Sixten's engineering department can verify compatibility between selected seal and hardware characteristics and, if necessary, propose changes to tolerances or roughness values.

For MOCA (Food Contact Materials and Objects) applications it is not enough to "choose a white gasket": very clear criteria are needed:

Material certified according to European regulations (e.g. EC 1935/2004 and 2023/2006) and, if required, also compatible with FDA regulations.

MOCA compliance statement provided by the manufacturer, with references to the batch and tests performed.

Compatibility with washing cycles/CIP: detergents, sanitizers, temperatures, and frequency of washing should be considered in material selection.

Site design to avoid stagnation, non-washable areas, and micro-cracks that are difficult to sanitize.

Sixten supports the customer from the material selection stage to technical documentation, providing custom MOCA holdings and specific directions for use in food, pharma and cosmetic lines.

Revamping by overhaul of sealing systems is particularly cost-effective when:

The mechanical structure of the machinery is still intact, but leaks, performance drops, or recurrent downtime occur.

The cost of downtime and complete replacement of the machinery is much higher than a targeted overhaul.

The original manufacturer no longer supplies spare parts or equivalent codes (dated machines, discontinued models).

- You want to improve performance with more modern materials and profiles (e.g., stronger seals at higher pressures, higher speeds, more intense cycles).

You want to adapt the plant to new regulatory or safety requirements without completely redesigning the machine.

Sixten, by analyzing the existing seals and operating conditions, can design an upgraded seal kit, improving the reliability of the machinery and extending its service life with a much lower investment than a complete replacement.

BLOG

Blog

Sixten ensures maximum safety in applications where the use of materials intended for contact with food, cosmetics and pharmaceuticals is required.

Disclosure requirements for public disbursements: state aid and de minimis aid received by our company are contained in the National Register of State Aid referred to in Art.52 of L. 234/2012 to which we refer and can be consulted at the following link: